With no one around for at least six weeks, the summer holidays provide the ideal window of opportunity for refurbishments to be carried out at school and college buildings.

However, having just six weeks to complete all areas of the refurbishments, can be a challenge for both contractors and manufacturers.

One of the main areas in a school that is often in need of an upgrade is the changing rooms and restrooms, including the cubicles. Working on refurbishing these facilities in such a short space of time can prove to be exceptionally difficult, without close co-operation from the panel manufacturer to deliver on time and with panels fully serviced.

As such, it is important that washroom suppliers ensure that they are working with a panel manufacturer that has extensive capabilities.

Here at Panel Systems we have one of the most advanced facilities for fabricating panels. This is due to our investment in the latest 5 axis CNC equipment, which enables us to take customers’ designs for panels and reproduce them on our sophisticated equipment, exactly as they designed them.

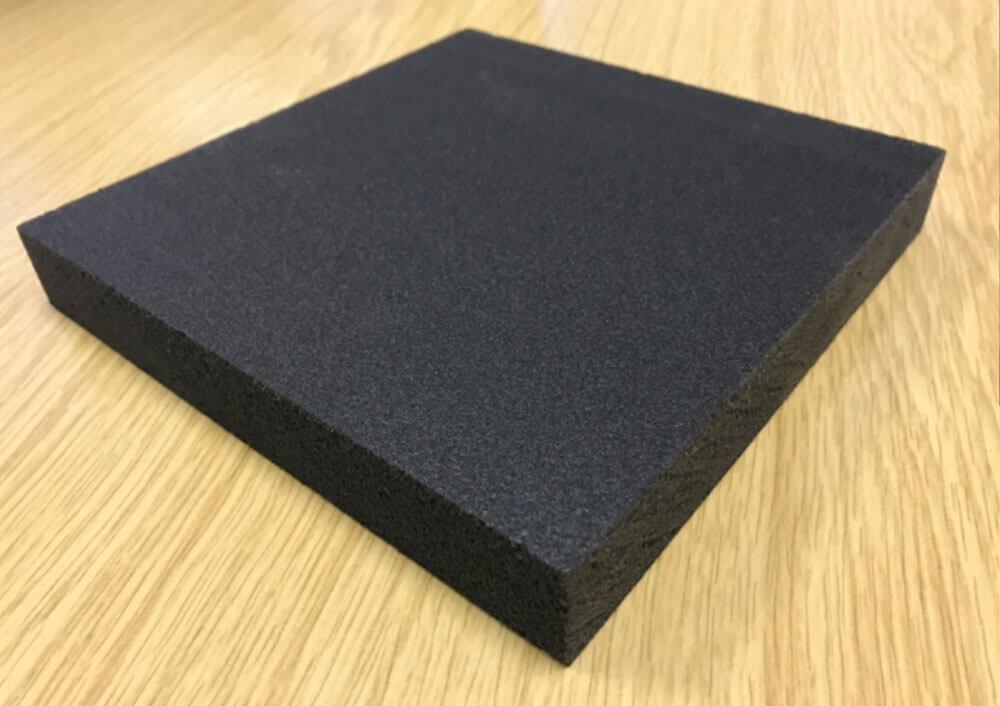

With both 3 and 5 axis CNC machinery, we are also able to provide more accurate and complex patterns and shapes in materials than ever before. The range of materials that we are able to work with is also more diverse and includes HDPE plastics, Solid Grade Laminates and also specialist lightweight sandwich panels.

These materials, plus many more, can be cut, shaped and routed using our CNC machinery, delivering bespoke panels with superior accuracy, precision and speed. Manufacturing with CNC means we are therefore able to offer higher quantities of precision made products with shorter turnaround times compared to manual machining. This includes routing out cubicle panels & lockers doors for hardware and adding any decorative detail that is required on the project.

Our skilled CAD/CAM team can also provide a tailored design service for standard and bespoke panels or customers can supply their own drawings in a variety of file formats including Solidworks and Alphacam.

Operating our own fleet of vehicles also means reduced lead times, as there is no need to wait for third party couriers to collect the panels – we schedule the delivery to meet with our client’s timeframes.

For more information, or for a quotation for your cubicle panel fabrication project, please contact our team on 0114 275 2881 or email sales@panelsystems.co.uk.