Solid Laminate Table Tops Cut to Size: CNC Machining by Panel Systems

CNC machined solid laminate tables tops are used across a huge number of applications and can offer a range of benefits. However, the way in which the material is cut can have an impact on the finished product and how it meets the specifications of a project.

CNC machining offers an accurate and highly beneficial method of cutting the material to suit the projects they’re specified for. When looking for cut to size solid laminate tabletops, knowing how they will be cut and the benefits of this process is important for making sure the finished product is cut to the correct size.

Introduction

In this guide:

- What is CNC machining? - Learn more about what CNC machining is and how it works.

- How are laminate tabletops cut using CNC machining? - Find out more about how laminate tabletops are cut to size.

- What are the benefits of using CNC machining? - Learn more about the benefits of using CNC machining to cut laminate tabletops.

- Who can benefit from cut to size laminate tabletops? - This section discusses the benefits and applications of laminate tabletops, find out more.

- The benefits of using Panel Systems as a supplier of cut to size laminate tabletops - Learn more about the benefits of choosing Panel Systems as your supplier of cut to size laminate tabletops.

What is CNC machining?

CNC machining is a manufacturing process during which the machinery and tools’ movement is driven by pre-coded computer software. Materials such as timber sheets, aluminium honeycomb, XPS Foam and solid grade laminate can be machined and cut into different shapes with ease.

The process uses computer aided design (CAD) files, to meet the specifications of a project. The machine is then programmed to cut the panel component into the desired shape.

At Panel Systems, we have a team of experts who can work with you to ensure the CAD designs are correct and that the material will meet your specifications once it has been cut. We work with you from initial specification through to the completion of your project and are able to do this as a result of our services being housed under one roof.

How are laminate tabletops cut using CNC manufacturing?

Our solid grade laminate tabletops begin life as a large sheet measuring up to 4.2m long. The material is then cut with a beam saw to the nearest size of your tabletop.

The material is then CNC machined to your bespoke size & shape to suit the needs of your project. The material can be cut into any shape, and the CNC machine can also insert additional holes where required.

Once the material has been cut and drilled to the correct shape and size, the edges can be machined with a bullnose detail to act as a feature and also to protect fingers from sharp edges.

CNC machining can also be used to machine special holes and recesses in the bottom of the tabletop in order that it can be attached to a table base. The holes can be blind holes or run through the tabletop to allow fixings to be attached. Precision and tolerance are important here to make sure the table can be properly fixed and is fit for purpose.

This process means you will be left with a fully complete tabletop, ready to be installed and used.

What are the benefits of using CNC machining?

There are many advantages to using a CNC machine to produce laminate tabletops compared to other methods. A few of the main advantages of using CNC machining for this process include:

High Precision

CNC machining allows for a high degree of accuracy and precision when cutting materials such as solid grade laminate. Access to the latest tool parts and ever more advanced software ensure that materials are cut to exact specifications every time.

Smooth Finish

CNC machining provides a smooth finish as it is cutting the material, which makes for a much higher quality product that is aesthetically pleasing as well as functional. Sharp edges can pose a hazard, especially for restaurant and bistro tables so not only will the CNC machine provide a smooth cut, it can also be used to ensure safety.

Dimensional Accuracy

CNC machining provides a high degree of dimensional accuracy which is how accurate the final product is in relation to the size and specifications of the original file, with little to no deviation.

Consistent Product Quality

All products cut with a CNC machine are programmed from an original CAD file. This means that CNC machining can ensure consistent product quality and a run of tabletops that are a uniform shape and size with no errors.

Production speed can be increased with a CNC machine due to the minimum of manual labour and lack of intervention and consistency of process.

Minimal Wastage

A CNC machine can take complete advantage of all available raw materials, thus minimising the amount of waste material produced. This helps a CNC operator minimize any loss that may occur in the manufacturing process, which has a knock-on effect of lowering overall cost when manufacturing laminate surfaces and other products.

Who can benefit from cut to size laminate tabletops?

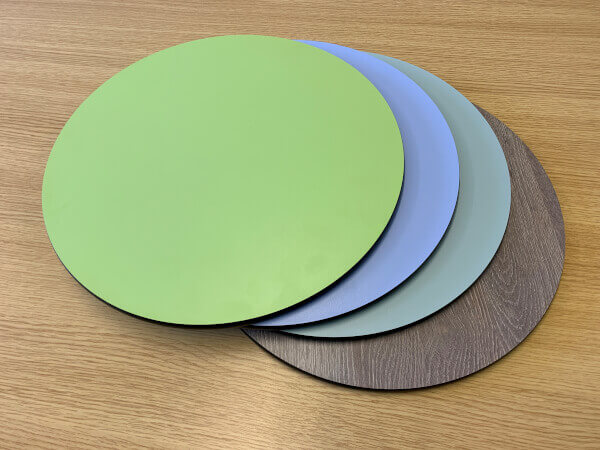

Laminate tabletops are beneficial for a wide range of applications and industries, due to its versatile nature and range of finishes and colours.

These tabletops are particularly beneficial for commercial table use such as:

- Restaurants

- Bars

- Cafes

- Countertops

- Worktops

The benefits of the material for these sectors include:

- Durability – laminate tabletops are durable and can withstand anything from piping hot crockery to repeated use. It will also stand up to harsh cleaning chemicals too.

- Easy to clean – laminate tabletops are easily wiped clean so turnaround time between customers in a commercial setting is lower, this is especially important for café or restaurant table tops.

- Range of colours and finishes – Solid laminate tabletops are available in 100’s of different colours and finishes including woodgrain, metallic and stone effects.

- Cost saving – due to the durable nature of the material, tabletops do not need to be replaced as often which can help to decrease long term costs for businesses.

To find out more about the uses, applications and benefits of laminate tabletops, read our guide.

The benefits of using Panel Systems as a supplier of cut to size laminate table tops

At Panel Systems, we have a huge range of experience with CNC machining a variety of materials across a number of industries and applications, with a diverse portfolio of clients.

Access to the latest/best tools

At Panel Systems, we have access to best and most modern CNC machining tools. Our CNC tools have both 3-axis and 5-axis capabilities. This allows us to create the most accurate designs and ensure that they are fit for purpose and will fit the project without having to make alterations or changes to the finished products. These tools also allow the materials to be cut with minimal wastage.

Quick project turnaround

Our experience and suite of modern CNC machinery mean that we can offer quick project turnarounds to ensure that you receive products in a timely manner and to meet budgets.

Bespoke projects

We also have the ability to cater for bespoke projects as well as mass-produced products. Whether you are outfitting a chain of restaurants or a boutique dining, Panel Systems provides a one-stop-shop for all your laminated tabletop requirements.

To find out more about our CNC machining service and laminate tabletops, please contact our expert team today.

Frequently asked questions

What are Solid Laminate Table Tops Used For?

Solid laminate table tops are versatile and durable surfaces commonly used in various settings. They are often found in commercial and hospitality environments such as restaurants, cafes, schools, and offices due to their resistance to scratches, stains, and moisture. Additionally, solid laminate table tops can be used in residential spaces for dining tables, kitchen counters, or workspaces because of their easy maintenance and wide range of colours and designs. Their sturdy construction makes them ideal for high-traffic areas where durability is essential.

Is Solid Grade Laminate Suitable for Outdoor Table Tops?

Upon request, Solid grade laminate is also available in a specific UV stable external grade for outdoor use. It is durable and resistant to scratches and stains and will hold up well against prolonged exposure to UV rays. If you're looking for materials for outdoor table tops, Solid grade laminate is an ideal choice of material that can withstand the elements better than more natural timber materials.

Are Solid Grade Laminate Table Tops Resistant to Heat and Moisture?

Yes, solid grade laminate table tops are designed to be resistant to heat and moisture. They are made from layers of thermally fused materials that provide durability and resistance to everyday wear and tear. However, while they can withstand some heat and moisture, it's still a good idea to use coasters or mats for hot items and to wipe up spills promptly to maintain their appearance and longevity.

What Maintenance is Required for Solid Laminate Table Tops?

Solid laminate table tops are relatively low maintenance, but to keep them looking their best, here are some simple care tips:

- Regular Cleaning: Wipe the surface with a damp cloth and mild soap to remove dust and spills. Avoid harsh chemicals that can damage the laminate.

- Avoid Abrasives: Use soft cloths or sponges for cleaning; abrasive pads can scratch the surface.

- Prevent Heat Damage: Use trivets or coasters under hot items to prevent heat damage, as extreme temperatures can warp or discolour laminate.

- Use Cutting Boards: To protect against scratches and cuts, always use cutting boards when preparing food. By following these maintenance tips, you can ensure your solid laminate table top stays in great condition for years to come!

Contact us

Get in touch to find out more about pricing, or to discuss your requirements in more detail.

Get in touch to find out more about pricing, or to discuss your requirements in more detail.

Call us on 0114 249 5626